Build Instructions (Version 3)

Before you start

- Skill level: beginner-friendly if you can 3D print + use a screwdriver.

- Time: first build usually takes a weekend.

- Goal: assemble + run the first motion test safely.

Rule #1: don’t force-fit parts. If it doesn’t fit, trim/sand gently.

1) Parts you’ll need (BOM)

Grab these parts before you start the build. Equivalent alternatives are fine as long as the specs match.

Bill of Materials

| Part | Qty | Buy link |

|---|---|---|

| ST3215-7.4v | x3 | |

| ST3020 25kg serial bus servos | x8 | |

| Newline 4K Webcam for PC with 2 Microphone, 1080P@60FPS, PDAF Autofocus in 1 Second, 12 Megapixels, Clear Stereo Sound, Auto Light Correction, USB Web Camera | x1 | |

| 7.5v 3000mah powr supply | x1 | |

| 5.5 × 2.1mm DC power connector adapters (male + female screw terminals) | x1 pack | |

| M3 countersunk machine screws (assortment) | x1 kit | |

| Deep Groove Ball Bearings 3×8×3mm | x1 pack | |

| MMOBIEL 20 AWG electrical wire (parallel), 5m | x1 |

Tip: buy the parts first, then do servo centering before assembly.

If you’re missing one part, don’t panic — Nova forgives you. Mostly.

2) Setup — Set Servo ID's and center your servos first (do this BEFORE printing/assembly)

This step is mandatory. If you install servos without setting ID's and centering them first, you’ll end up with joints that hit hard stops, bind, or move off-angle (or worse: don’t respond to commands) — and it’s painful to fix later.

Do this first

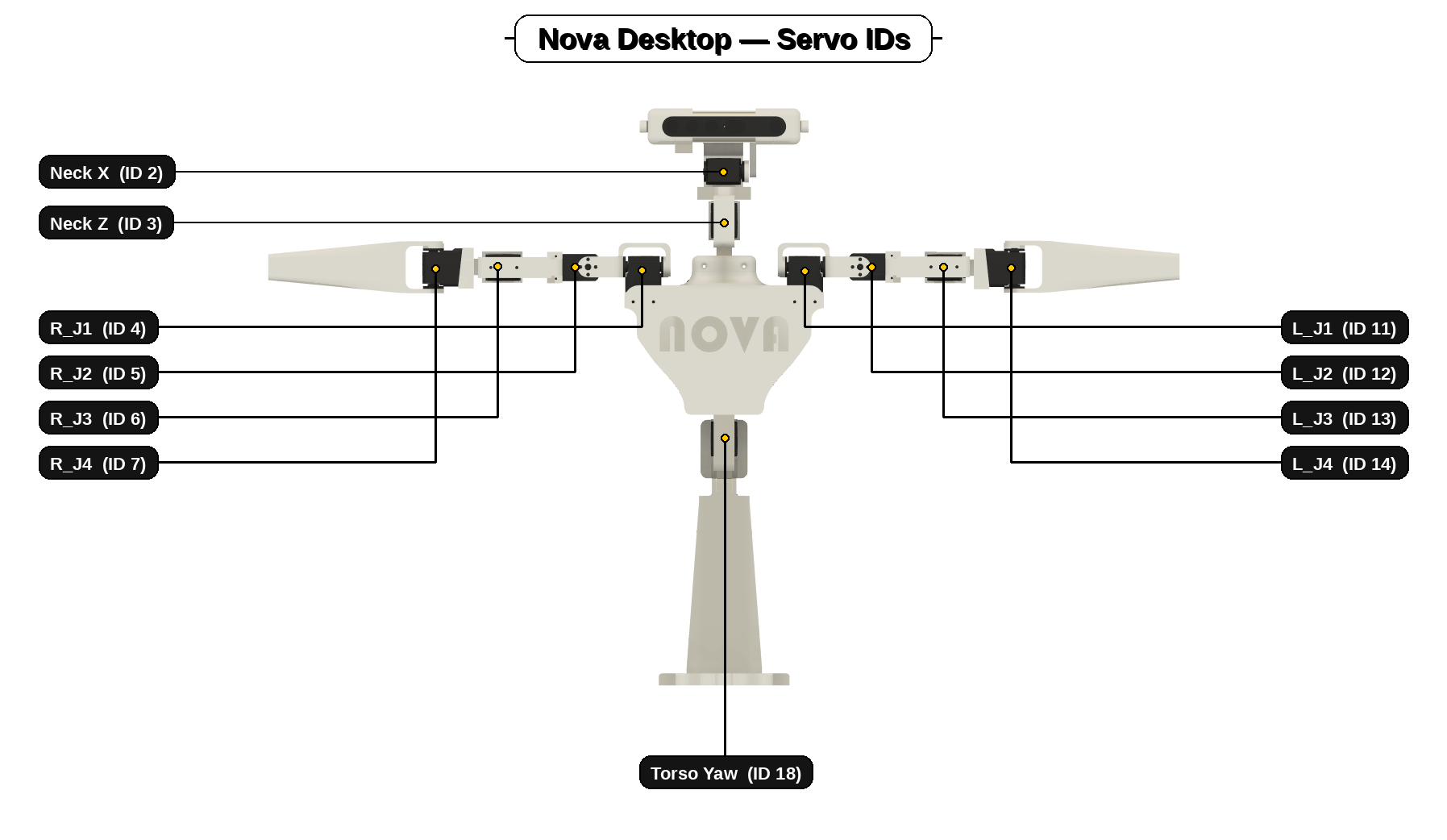

- Set servo IDs. Make sure every servo has the correct ID for its joint (see the map above).

- Center every servo. Set each servo to its neutral/middle position before attaching horns and brackets.

- Only then assemble. Building around centered servos prevents binding and makes the “neutral pose” line up cleanly.

If a horn can’t be perfectly straight because of spline steps: choose the closest, then correct with a tiny software offset later.

3) Servo driver setup (ESP32) — upload code + Wi-Fi details

Do this early. Once your ESP32 boards are configured and online, the rest of the build is much smoother.

Steps

-

Open the ESP32 code in the Arduino IDE.

Open the arm driver sketch and the torso+neck driver sketch. -

Set your Wi-Fi name + password in the code.

Replace the SSID and password in each sketch with your own router details. -

Set your computer IP address (UDP target).

You’ll need your laptop/PC IPv4 address in the sketches. On Windows run ipconfig and copy your IPv4 Address. -

Upload the sketches to the ESP32 boards.

Flash each board (arm board + torso/neck board). -

Confirm Wi-Fi connection (status LED).

When it connects successfully, the little white dot/LED flashes on and off. That blinking is your “all good” signal.

Tip: keep the rear door open while doing this so you can access the boards easily.

4) Build Order (Recommended Sequence)

Print order matters. This sequence avoids rework and makes wiring + assembly much easier.

Recommended sequence

- Print the base first. Stable foundation — everything mounts cleanly once the base is solid.

- Print the torso next. The torso is the main hub — electronics and modules plug into it.

-

Mount the servo drivers to the chest rear door (off the torso).

Recommended layout: arm driver at the top, torso+neck driver at the bottom. - Join torso housings + attach the rear door (don’t close it yet). Keep access open for wiring and plugs.

- Print arms + neck (any order). They’re modular and slot into the torso once ready.

Core idea: mount electronics early, keep access open until all servos are connected, then close up.

5) Arm Build

Build both arms the same way. Clean routing = smooth life.

Steps

- Print the arm parts. Clean supports and test-fit before committing to screws.

-

Install centered servos, building outward (shoulder → forearm).

Start at the first shoulder joint, build one joint at a time, and keep the arm laid out straight at neutral. - Route servo cables as you assemble. Leave slack at joints and avoid pinch points.

-

Slot arms into the torso, screw in, then plug into the arm driver.

Do this while the rear door is still open so everything stays tidy.

Tip: if anything binds, stop and check horn alignment — don’t “force” the joint past resistance.

6) Neck Build

The neck is modular — build it as a clean sub-assembly, then slot it into the torso.

Steps

- Print the neck parts. Clean supports and test-fit first.

- Install centered servos + assemble the neck mechanism. Centered servos = head sits straight at neutral.

- Route cables (leave slack for full motion). Make sure wires can’t snag when turning/nodding.

- Slot neck into torso, screw in, then plug into torso+neck driver. Do this before closing the rear door.

Tip: manually sweep yaw/pitch by hand before power-on — you’re checking for snags and pinch points.

7) Head + Camera Fitment (USB camera + clips) — fiddly bit

The head can be fiddly. Take it slow and don’t force it — tiny alignment tweaks make a big difference.

Install the camera (Version 3)

This step mounts the camera into the head pivot arms so it can pitch smoothly without binding. Getting the alignment right here massively improves face tracking stability.

-

Make sure the pitch servo is centred.

Before fitting the camera, set the pitch servo to its middle/neutral position (the same centre you used in the servo centering step). This ensures the camera starts from a level “straight ahead” pose. -

Place the camera between the mount arms.

Slide the camera body into the gap between the two mount arms and ensure it’s pointing directly forwards. Keep it square — not twisted or tilted — so the pivot feels smooth. -

Start the bolts with washers (2 per side).

On one side, screw in a bolt and slide two washers into the gap between the camera and the arm. Lightly tighten the bolt so it holds, but can still pivot.

Repeat on the other side: bolt + two washers, lightly tightened. -

Fully tighten + hand test the pivot.

Tighten both bolts fully (snug, don’t over-torque). Then manually pitch the camera up/down with your hand. It should pivot smoothly without sticking or wobbling.

If the pivot feels tight: re-seat the washers and make sure the camera is centred in the gap. If it feels loose: confirm you used two washers per side and that both bolts are snug.